Over the past couple of months we have been receiving an assortment of questions in regards to our products. We thought it would be a good idea to share the more popular questions and answers as they stream in to keep everyone updated.

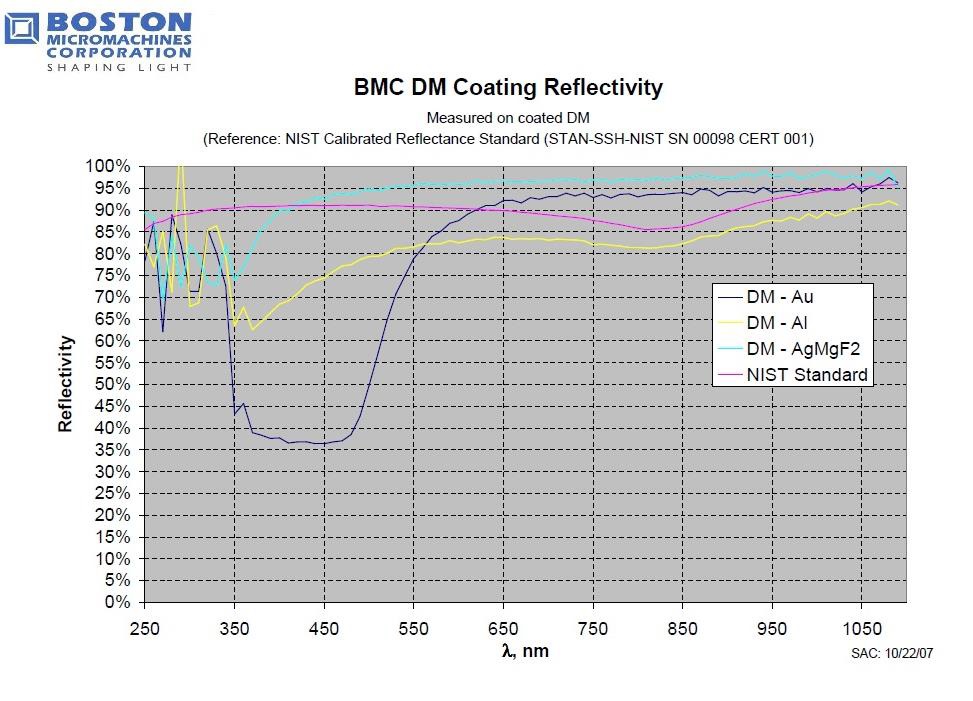

One question that tends to be asked quite often is the reflectivity our deformable mirrors can achieve. This depends on a couple of factors such as mirror coating, protective window AR coating and the wavelength of the light.

We offer gold, aluminum and protected silver coating on almost all of our deformable mirrors. When selecting a coating, you should pay particular attention to the wavelength(s) of light you use.

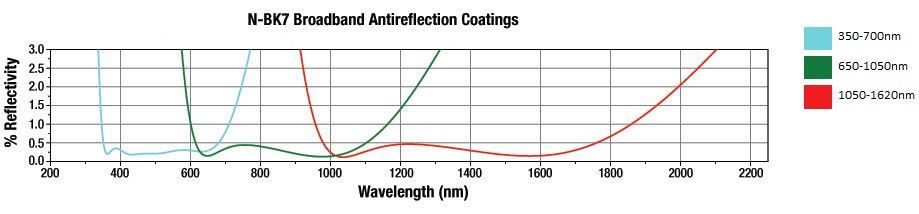

Our standard windows with AR coating are BK-7. We offer a few options, depending on which size mirror you select. For our smaller DMs, we offer the standard coatings from Thorlabs as well as a few more versatile options. You may choose either uncoated, 350-700nm, 650-1050nm or 1050-1620nm. We also offer a 400-1100nm window and 550-2400nm, the latter for an additional cost. For our larger DMs, various coating options are available.

The N-BK7 Broadband Antireflection Coatings chart from Thorlabsbelow depicts the percentage of light lost for each AR coated window. Similar curves are available for our other coatings.

If you are looking for additional information on our standard windows, please visit our friends atThorlabsonline.

Check more

Related Articles

Defense TechConnect Conference and Expo: Fun in the Sun with the MRR

Last week I was fortunate enough to be able to parade BMC’s Modulating RetroReflector (MRR) in front of multiple audiences affiliated with the Defense community at the Defense TechConnect (DTC) Conference and Expo in Tampa, Florida.

MiFoBio 2018: AO Microscopy in Action

Recently, Boston Micromachines sponsored MiFoBio (Functional Microscopy in Biology), an event that brought together the microscopy community, academics and professionals alike, to attend courses and workshops that explored the understanding and current trends of biological imaging.